Project Description

Do You Have A Construction Project We Can Help With?

OVERVIEW OF CTI INDUSTRIES, INC.

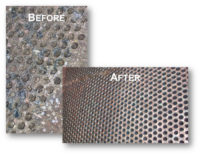

CTI Industries, Inc. developed its patented Shield/Seal” repair for condenser and heat exchanger tube in 1976. The repair technique involves the installation of thin-walled alloy inserts – CTI Shield/ShieldsTM – into damaged tube ends. The “Shields” are fabricated from a variety of erosion resistant alloys based on the parent tubes and their failure mechanism. Tube ends are cleaned, the Shields installed and expanded into the existing tubes. The Shield/Seal repair method can save up to 90% versus the cost of traditional retubing.

CTI has installed more than 5 million Shield/SealsTM in 32 countries around the world. Our Customers include electric utilities, refineries, commercial marine, desalination plants, paper mills and other industrial sites. Shield/Seals are used exclusively on board U.S. Navy Ships, from frigates to aircraft carriers.

CTI has also developed the technology for repairing failing or plugged tubes with Full Length

Tube LinersTM – another restoration process patented by CTI. The “liners” are thin walled tubes selected from a number of different alloys. Plugs are removed, tube I.D.’s cleaned and liners installed. They are then hydraulically expanded to intimately fit the existing tubes, ensuring maximum heat transfer. Finally, the liners are trimmed flush and mechanically expanded at the tube sheet areas resulting in a fully restored tube.

In addition, CTI offers a variety of tube cleaning techniques, inspection services and epoxy coating applications.

With offices in Stratford, CT, San Diego, CA, Dubai, and U.A.E. – and representation in most parts of the world – CTI is positioned to provide our services worldwide.

Project Details

DATE

December 18th, 2015

CLIENT

Client Company Name

PROJECT TYPE

Commercial

CONTRACTOR

ThemeFusion Company